Have you tried more penetrating fluid, heat and mole grips since you drilled it ?

Will do, thanks.

Indeed, pin wasn’t moving at all as before.

At this point, however, I have it drilled out so only the thread part of the pin is intact, nothing of the pin that can be gripped is left.

a lot of the underground is held together with helicoils, dont see them fail often

Well, I was self-isolating there for a couple of weeks, but just before I did I ordered the helicoil to arrive to my workplace instead of home  Finally, got hold of it. But, of course, my drill only supports drill bits up to 10mm, and the one I need to use from the kit is 10.5mm…

Finally, got hold of it. But, of course, my drill only supports drill bits up to 10mm, and the one I need to use from the kit is 10.5mm…

You speak like this is a bad thing?

You’ve now got a valid excuse to buy more tools. That’s never a bad thing!

Hah, normally I’m all for it. It’s just bad timing. I bought my drill just half a year ago, didn’t even realize I might come across this kind of limitation.

Would one of these type of chuck adaptors work?

https://www.amazon.co.uk/Keyless-Adapter-2-20UNF-Professional-Converter/dp/B07MR2TSCX

Probably. However, I think a reduced shank drill bit would possibly be a more accurate & cheaper option.

NO - 10 mm (3/8") chuck drills have a smaller chuck spindle to 13 mm (1/2") chuck drills.

You have three options

-

The reduced shank drill bit idea should work even though the drill will be working over its maximum cutting capacity in metal.

-

Something like this 240v MacAlister 13 mm drill off the shelf in Screwfix for £24.99.

-

For a one off use borrow a 13 mm drill off a neighbour, friend, Father-in-Law or @Jay

Where do you live Slacker ?

You’re more than welcome to borrow a drill from me if you’re not too far away.

Just had a look in the garage and I’ve got one you can have.

@Pat Yeah, that seems like a better option in this case.

@National_Treasure Thanks. I’ll keep the drill in mind if I need more use of the bigger bits, for now I’ll go with a reduced shank drill bit. Should be fine for such a small job, I guess.

@Longshanks Thanks for the offer. I ordered the drill bit already (it was just over one quid). But if that doesn’t work out, I might hit you up.

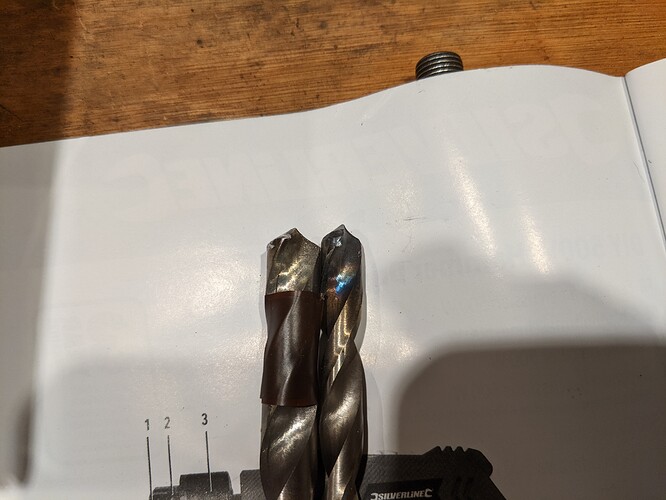

The reduced shank drill bit didn’t pan out. Wasn’t doing much when I was trying to drill the hole. Thought maybe as mentioned the drill is a bit too weak for that. So, went ahead and ordered a cheapo corded drill with a bigger chuck. And, what do you know, still not getting much further with the more powerful drill and the drill bits from the helicoil kit. All I seem to be doing is widening the first few mm of the hole, but not going any deeper at all after going at it a few minutes at a time. Tried a smaller drill bit from the kit, same result, but the bit burned a little. Maybe I don’t know how to use a drill ![]()

Are you drilling clockwise? Drilling in reverse will.just get everything hot.

…that caliper is looking a bit mashed now…

I am drilling clockwise. That is the forward direction, correct?

Yeah, the caliper has seen better days. But it’s not mainly about the caliper anymore. I’ve already bought a used one off ebay which I’m using on my bike. But I’d still like to see this through if possible. For practice if anything else.

You might be using too much speed and not enough pressure.

A drop of cutting oil will help too.

If the pin is made of stainless steel a cobalt drill bit should do it.

That’s the sort of thing I’d do, carry on even when it’s not necessary, accept the challenge!

Slow down, use an oil for cooling, 3-in-1 oil is good enough.

It looks like the start of the hole has been deformed by drill bit chatter, this is where the drill bit has been bouncing around instead of cutting, the main causes of chatter are too fast drill speed, insufficient or no cooling, drilling off square to the piloting hole, too much or too little pressure on the drill tip.

+1 Top tip right there from Mian - Slow drill speed and a thin oil. The 3-1 is a machine oil and a very useable substitute for a cutting oil and would be my first choice for drilling into a blind hole. To drill into a through hole I’d use a constant spray or drip feed of dishwasher water, in the machine shop we used ‘suds’ a very thin emulsified mix of oil and water, its mostly for its cooling properties but a little lubrication helps too. Suds looks and feels like milk but tastes and smells very different as many an engineering workshop apprentice boy will tell you. You’ll need two pair of hands, one pair drilling and the other pair constantly spraying or drip feeding the dishwasher water or thin oil. The idea is to keep the drill bit cutting edge wet and cool.

Remember slow drill speed, steady drill tip pressure, keep the caliper steady, drill square to the piloting hole and keep the drill bit cutting wet with a coolant.

Make sure hammer action is off .

Calipers are Hardened Steel and even carbide tipped bits can struggle .

Plus if the helicoil kit is of a budget price don’t expect the bits to be the best quality but due to their weird size it’s hard to source a quality replacement

As suggested, I’ve used the cutting oil with reduced drill speed and average pressure. It did start to very slowly go deeper, but still kind of a pita. Then I tried a cobalt drill bit, and the bit went through the caliper like butter. A little too well mayhaps as you can tell from the photo below ![]()

Decided to give it another go, so cut off the bunged up part and drilled again. Wasn’t trying to be too accurate, so it’s a bit off-centre but drilled, tapped and helicoil installed. I shall call this a partial success, will be much better the next time I need to do this.

Thanks, lads. This has been educational and fun if nothing else.

Perfect repair! Get that back on the bike and go for a ride…