Argh!

It’s bank holiday weekend, and instead of being out on mine, I’m stuck under my parent’s (shared) bike - they’re still ‘learning’ so they’re on a 125… and I can’t get the carbs right…

I managed to check/balance/clean and set the carbs on my RF, but this *******ing little 125 won’t fire.

I know a little trick about jetting a little brake cleaner into the air box to get things started… i’ve had to do it to mine (old bike) a couple of times on icy mornings… and if i do that on mine it’s fine… on the RT 125, the bike starts… and proceeds to red-line itself until I cut the fuel supply off.

In summary…

It won’t start without a little help, but once it’s running, it revs high (11,000, 1,000 over the red-line) until the fuel has been consumed (I usually hit the kill switch or, knock the fuel **** off)…

I’m not shy about taking the carbs off again, and they’ve all been done over top-bottom with carb cleaner and brake cleaner (for the really ****-up bits)

Bike: 2003 MZ RT 125

Please Help!

sounds like the throttle has stuck open or the slider is jamming

Hiya,

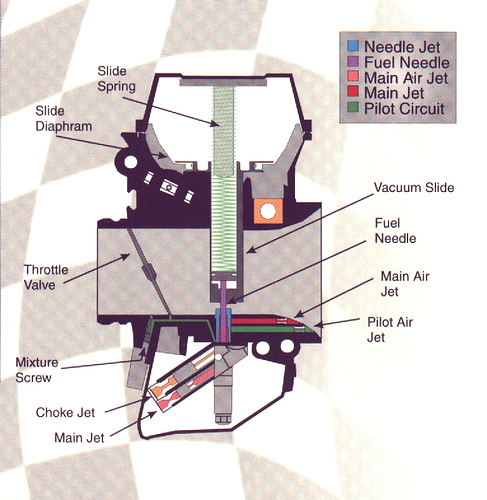

Thanks - It’s idling about 9,000 RPM now, I messed with a tiny little screw inside, and I cleaned the main throttle needle and lubed it up… carb cleaner and WD40 helped a lot! I really wish there were a better resource online for carbs and their generic format and fixing!!

I’m thinking of braving some 3d software, and seeing if I can come up with a model of a generic looking carb, but i’m afraid I don’t know enough about how they work to do it accuratly!

Can anyone think of anything else to try?

I’m going to go back in and mess with that screw again in the morning!

If I could describe where it was, and what it did, I’d say it’s at the ‘cylinder’ (engine) end of the carb, directly in the middle… spraying carb cleaner into it (with the screw 100% out) comes out in two places, once directly above the screw, and once almost directly in the middle of the carb, near the main throttle needle. The screw itself is an elongated needle, with a screw thread on the bottom, also there’s a spring - but I don’t know how that is supposed to work, becase the thread holds it in securely…

Help!!

Update (attached)

Which way should I put the mixture screw to find a happy medium? In or out?

Attachments

u start with the needle full in then turn out 2 to 2 1/2 turns depending of bike.all needles start fully closed then turn out.hope this helps but i sort them out by trial and error normally.has the throttle cable been oiled inside that could be sticking.

Thanks for keeping your eye on this thread steve!

Throttle cable was a bit funny looking, but I WD-40’ed it to death, and it’s a tonne better, I’m not sure if theres a better lube I could by using, but that seemed to do the trick!

Lee H

Why wouldn’t it fire? Dirty carbs/fuel, so you take them apart clean them, put it back together… but it still does not want to fire, because kak in the pipes is sucked in again straight away. If the fuel is more then a couple of months old it could have gone off, have water in. Its a good idea if the bike stands for any length of time to drain the tank and start again. You could end up taking the carbs apart and cleaning them two or three times otherwise.

The screws to adjust the syncronisation of the carbs should be in between each carb. They just adjust the opening of the throttle butterflies. If you mess around with the little screw on the carb itself, its not good. These are pre set by the factory and you are not supposed to fiddle with neddles! If you took the carbs apart and put them back together again you could have got a spring in the wrong place. Check throttle is closed, check cables are set correctly and that the throttle butterfly open and close again.

now if all else fails go to ebay and buy some more

here it is explained a bit better.

A carburettor is basically a shaped tube. The shape of the tube is designed to swirl the incoming air and generate a vacuum in a section called the venturi pipe (or just the venturi). In the side of the venturi is a fuel jet which is basically a tiny hole connected to the float chamber via a pipe. It’s normally made of brass and has a miniscule hole in the end of it which determines the flow of fuel through it. In more complex carburettors, this is an adjustable needle valve where a screw on the outside of the carburettor can screw a needle in and out of the valve to give some tuning control over the fuel flow (EG DON’T MESS WITH THIS IS YOU DON’T KNOW WHAT YOU ARE DOING). The fuel is pulled through the jet by the vacuum created in the venturi. At the bottom of the tube is a throttle plate or throttle butterfly which is basically a flat circular plate that pivots along its centreline. It is connected mechanically to the accelerator pedal or twist-grip throttle via the throttle cable. The more you push on the accelerator or twist open the throttle, the more the throttle butterfly opens. This allows more air in which creates more vacuum, which draws more fuel through the fuel jet and gives a larger fuel-air charge to the cylinder, resulting in acceleration.

When the throttle is closed, the throttle butterfly in the carburettor is also closed. This means the engine is trying to suck fuel-air mix and generating a vacuum behind the butterfly valve so the regular fuel jet won’t work. To allow the engine to idle without shutting off completely, a second fuel jet known as the idle valve is screwed into the venturi downwind of the throttle butterfly. This allows just enough fuel to get into the cylinders to keep the engine ticking over.

yeah, i ****ed them - i mesed with the mix needle… and t’s booked in the local shop for the 16th…

… my fettling managed to get it idling at 4,000 and reving properly… but not reving down on its own accord!

)ps. there is only one carb!(